Heli

Basic Info.

| Model NO. | K9tl2-40301 |

| Certification | IATF16949 ISO9001 ISO14001 OHSAS118001 ISO3834-2 |

| Color | Black |

| Support Forklift Brand | Heli JAC Hyster |

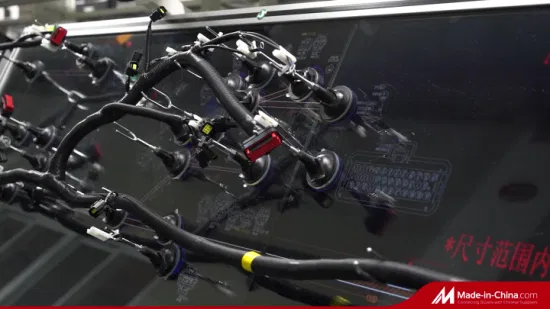

| Craftsmanship | Flexible Visual Assembly Line |

| Transport Package | Box |

| Specification | 1 kg; 2900mm overall length |

| Trademark | HAJX |

| Origin | Hefei, Anhui, China |

| HS Code | 84312090 |

| Production Capacity | 150, 000-200, 000 Pieces/Year |

Product Description

Product Description| Product Name and Model | Wiring Harness-ABG72-40041 |

| Product Description | Lithium-ion new model body wiring harness, using spray code line, shield line process |

| Production Process | Wire cutting - Crimping - Pre-assembly - Wrapping - Conductivity testing |

| Materials | FLRY-B German standard line + TE and other brand plug connector |

| Surface Finishing | Outer sleeve corrugated pipe / PVC pipe protection |

| Product weight | 2KG |

| Product appearance installation size | Diameter φ23, total length 4900mm |

| Product advantages 1 | More than 2000 types of products involving internal combustion, electric, heavy-duty vehicles and port transport machinery, with tonnage covering 0.5-46 tons forklift series |

| Product advantages 2 | The products adopt advanced technology, processing once, streamline operation, stable product quality and traceability. Manufacturing adopts MES system 4M management, with WMS and AGV to realize the whole process control of raw material supply - manufacturing - storage |

| Product advantages 3 | The products have 9 patented technologies and have reached an advanced level in the industry in terms of resistance to current, temperature, humidity, salt spray, vibration, industrial solvents, flame retardancy, etc. |

Hefei He An Machinery Manufacturing Co., Ltd, which was set up in 1981, is the subsidiary of Anhui Forklift Truck Group Co., Ltd. The company is the professional industrial vehicle parts manufacturer, and is located at National-level economic and technological development zone, the shore of Chaohu in Hefei, Anhui which is called"Once familiar place of the Three Kingdoms, New town of science and education". The area of the factory site is 40000 square meter.

The company constructs a perfect product research platform, and has all kinds of 60 professional technicians. The products are implemented as the standardized and modular design, and independent research and development achievements have acquired more than 90 patents authorization for invention. The technical center has passed the certification of provincial enterprise technology center, industrial design center and the certification of municipal engineering and technological research center.

The company implements the total quality management sustainably and has successfully passed the IATF16949, ISO9001, ISO14001, OHSAS18001 and ISO3834-2 certification, the National high-tech enterprise certification, the National safety quality standardization machinery manufacturing second level enterprise certification, certification of the National two integration management system, certification of Anhui intellectual property standard, certification of Anhui pilot demonstration enterprise of manufacturing industry and internet convergence Development, brand demonstration enterprise certification of Hefei, certification of Hefei smart factory, certification of Hefei digital workshop, certification of outstanding enterprise of Feixi County etc...Furthermore, the company has been awarded with honorary titles, such as the National "Five-star" scene of working groups, the top-ten integrity of industrial enterprise etc...

The company always adheres to the core value "Put People First, Repay the Society with High Quality Products", "Service"as the purpose, "Responsibility"as the motivation, and comprehensively boosts and goes deep into Lean Production, innovative approach, scientific management and strives to make industrial vehicle parts significant manufacturing base.

The company implements the total quality management sustainably and has successfully passed the IATF16949, ISO9001, ISO14001, OHSAS118001 and ISO3834-2 certification, the National high-tech enterprise certification, the National safety quality standardization machinery manufacturing second level enterprise certification, certification of the National two integration management system, certification of Anhui intellectual property standard, certification of Anhui pilot demonstration enterprise of manufacturing industry and internet convergence Development, brand demonstration enterprise certification of Hefei, certification of Hefei smart factory, certification of Hefei digital workshop, certification of outstanding enterprise of Feixi County etc.. Furthermore, the company has been awarded with honorary titles, such as the National "Five-star" scene of working groups, the top-ten integrity of industrial enterprise etc..

The company has the advanced manufacturing capacity in the domestic industry. Taking Automation, Informatization, and Intellectualization of production manufacturing as the core, the company scientifically applies to use SAP, MES, WMS, BPM and other information systems, and successfully set up the Automated High-rise Warehouse and AGV Intelligent warehousing and logistics Distribution System. The company has over 20 production lines such as visual wiring harness assembly lines and modern suppressor lines. Besides, it also has more than 40 sets of welding robot and over 400 sets of advanced production equipment such as high-power fiber laser cutting machine, 3d laser cutting machine, CNC vertical machining center, CNC vertical drilling and milling center, CNC turning center, CNC pipe bending machine, CNC bending machine, fully automatic metal cutting machine, CNC hydraulic shearing machine, flat steel automatic cutting machine, automatic terminal pressure wear bolt machine and so on.